Considerations for Selecting a Hose Assembly Solution

| Temperature | Identify the minimum and maximum temperatures the hose assembly will be exposed to with regard to the system media and the environment. |

|---|---|

| Pressure | Identify the minimum and maximum pressures (or vacuum) within and outside the hose assembly. |

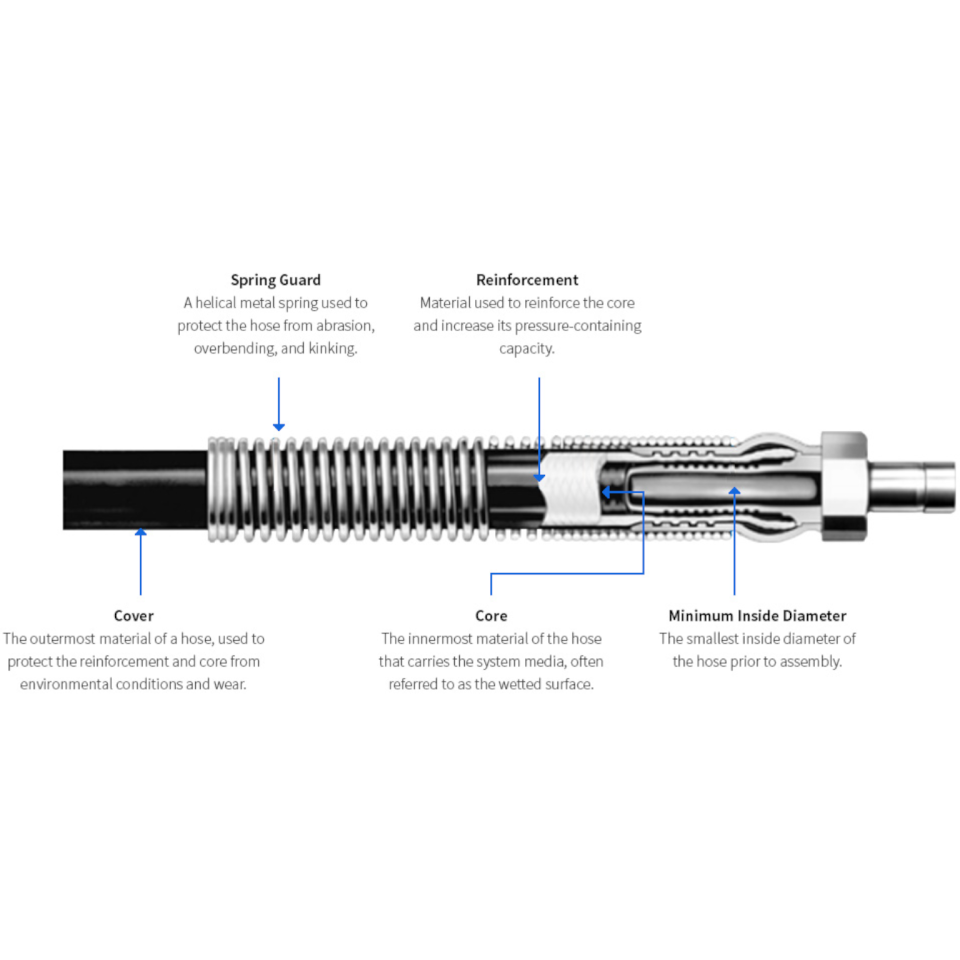

| Material | Identify the system media and the environment to which the hose assembly will be exposed. This will help determinethe materials of construction best suited to the applicationdemands and whether the hose requires a static dissipativecore. |

| Movement | Confirm whether the hose assembly will be installedin dynamic applications as this will require differentconsiderations than a static application. |

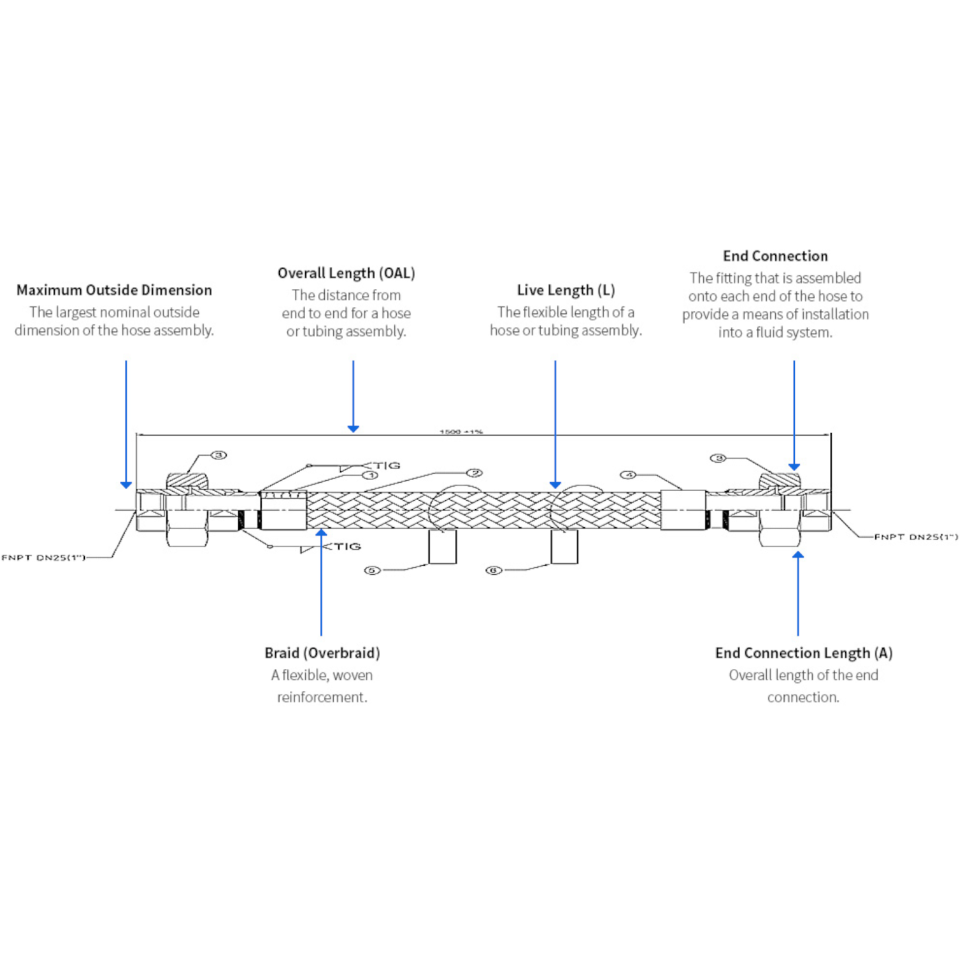

| Length | Determine the most likely route for installation of the hose, and use this to identify length requirements. |

| Cleanliness | Identify the need for cleanliness. Ease of cleaning the internal surfaces of the hose, as well as maintaining outside cleanliness may be of concern. |

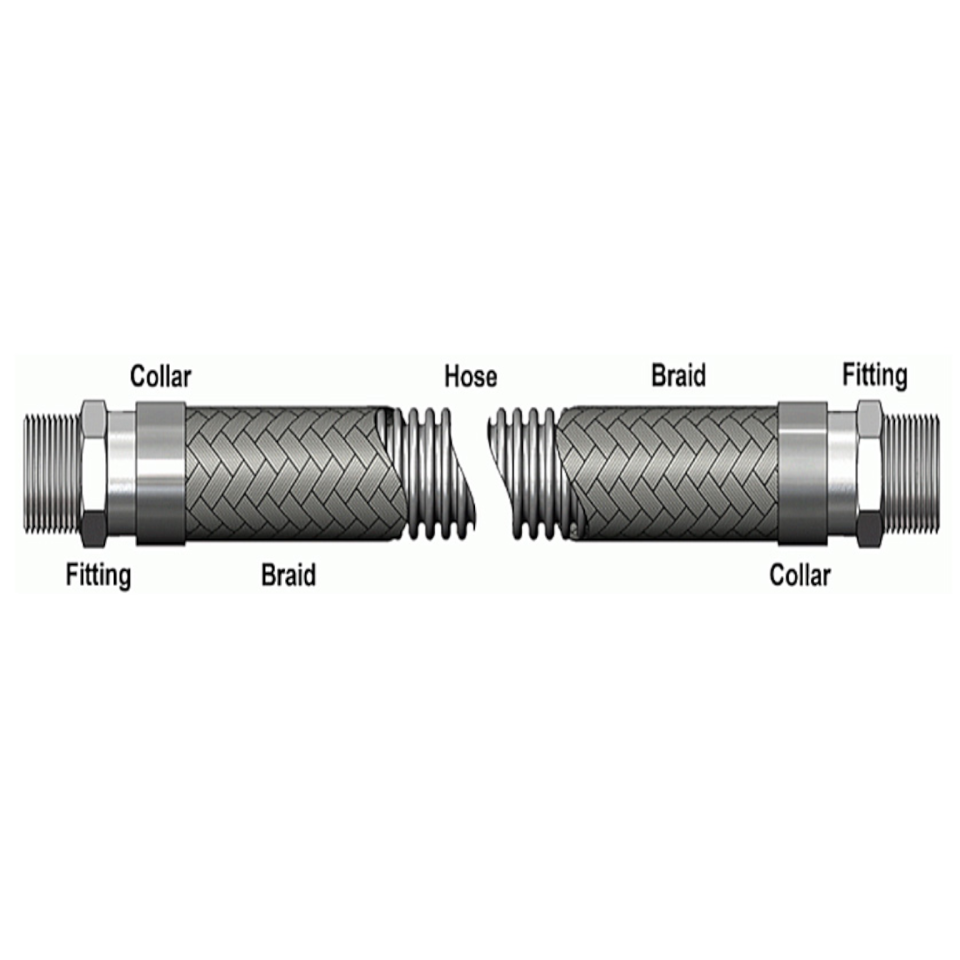

| End Connection | Identify the type of end connections which are most compatible with the system requirements. End connections differ with regard to materials of construction and pressure ratings. |

| Orientation | Clarify space constraint concerns. Hose assemblies with elbows and union ball joints may help resolve space constraint issues. |

| Desired Flow | Consider desired flow. Hose connection size, core tube construction, and routed installation may impact flow. |

| Drainability | Consider core construction as this will impact drainability. Test ReportsIdentify the need for documentation in the form of testreports. |

| Special Marking | Discuss special marking requirements; there are different options available to readily identify hose assemblies. |

|

Documentation and

Regulatory Requirements

|

Identify the need for special regulatory approvals or documentation. |

|

Additional Protection

and Covers

|

Identify whether covers are necessary for additional protection of the hose assemblies or surrounding systems. |

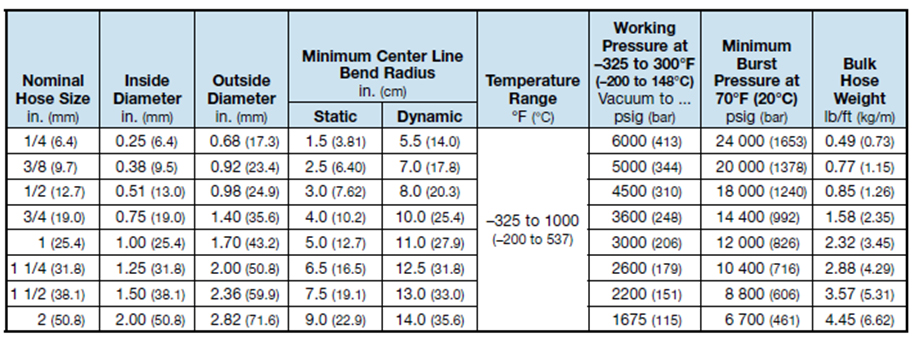

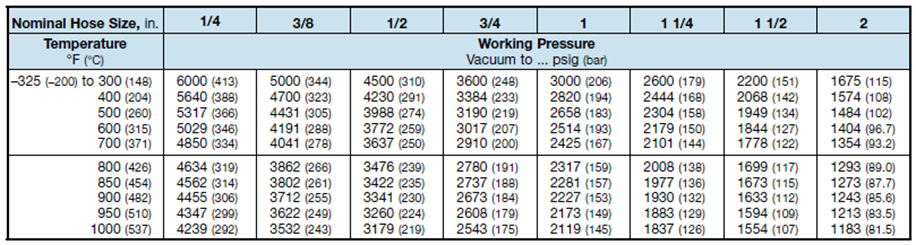

FX Series (High-pressure Flexible Metal Hose)

-

-

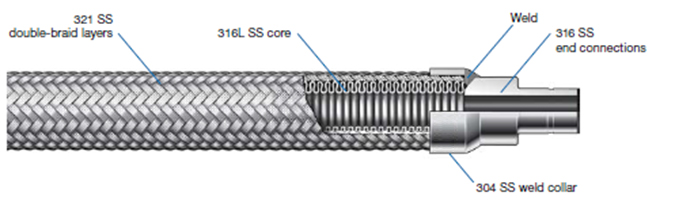

- High-pressure corrosion resistant all-metal hose.

- 316L stainless steel annular convoluted core.

- Size range of 1/4 through 2 in. and working pressures from vacuum to 6000 psig (413 bar).

- Double braid layers of 321 stainless steel promotes hose pressure containment.

- End connections welded in accordance with ASME Boiler and Pressure Vessel Code Section IX

- Commonly used in high-temperature vacuum and high-pressure corrosive environments or where permeation is undesirable.

- Standard and custom assemblies available.

- Options include hose covers, hose tags, and additional helium leak testing.

-

Pressure-temperature ratings may be limited by the end connections.

Ratings are based on ASME Code for Pressure Piping B31.3, Process Piping.

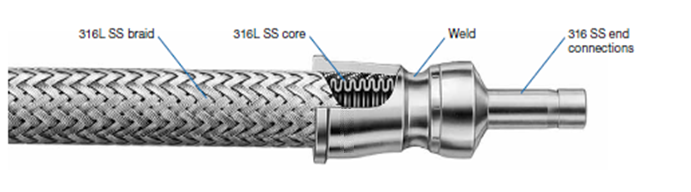

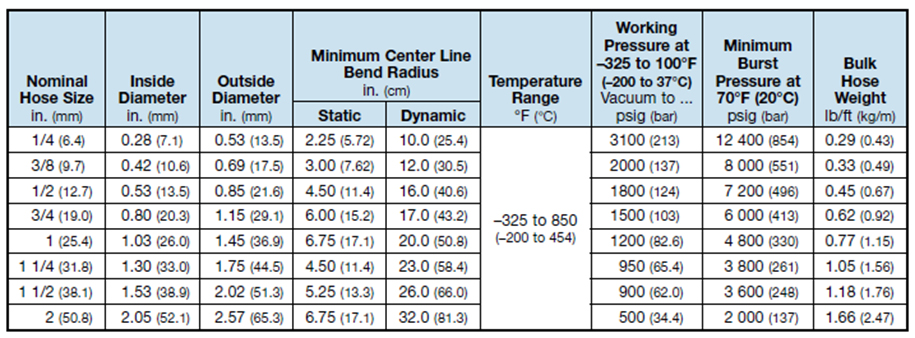

FM Series (Flexible Metal Hose)

-

-

- All-metal hose promotes corrosion resistance.

- 316L stainless steel annular convoluted core.

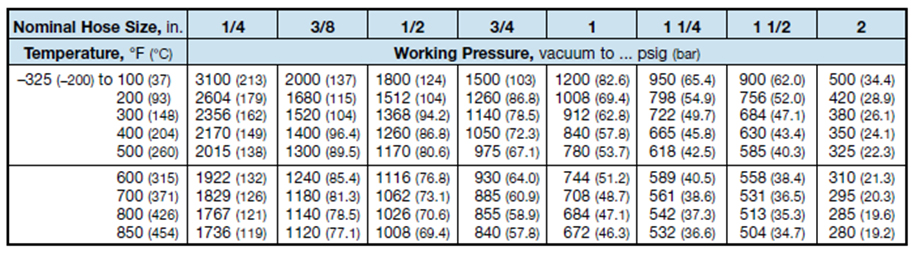

- Size range of 1/4 through 2 in. and working pressures from vacuum to 3100 psig (213 bar).

- Single braid layer of 316L stainless steel promotes hose pressure containment and exhibits strong performance in dynamic cycling applications.

- End connections welded in accordance with ASME Boiler and Pressure Vessel Code Section IX.

- Commonly used in high-temperature vacuum applications and medium-pressure corrosive environments, or where permeation is undesirable.

- Standard and custom assemblies available.

- Options include hose covers, hose tags, and additional helium leak testing.

- All-metal hose promotes corrosion resistance.

-

Ratings are based on ASME Code for Pressure Piping B31.3, Process Piping.

Options

FOR MULTIPLE OPTIONS,ADD DESIGNATORS WITH A DASH BETWEEN EACH DESIGNATOR.

| CRN | LANYARD TAG WITH CRN |

|---|---|

| A | ARMOR GUARD |

| F | FIRE JACKET |

| G | CGA 4.1 CLEANING ON HOSE WETTED SURFACES |

| F1 | THERMOSLEEVE |

| H7 | HELIUM LEAK TEST (1Ⅹ10_7STD CM3/S) |

| N3 | NITROGN PRESSURE TEST |

| Z | 316L SS BRAID MATERIAL |

| S | 302 SS spring guard, hose-length (1/4, 3/8 and ½ in. only) * FM Series |

| W | Hydrostatic test * FM Series |

MAT TAGS

| MA | GRAY |

|---|---|

| MG | GREEN |

| MO | ORANGE |

| MB | BLUE |

| MK | BLACK |

| MP | PURPLE |

| MC | BROWN |

| MN | PINK |

| MR | RED |

| MW | White |

| MY | Yellow |

|

ADD 2 TO THE END OF THE MAT TAG DESIGNATOR FOR TWO TAGS.

EXAMPLE : MA2

|

|