Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

|---|---|---|---|---|---|---|---|---|

| ≤0.020 | 0.5 | 1.8 | ≤0.025 | ≤0.015 | 20 | 25 | 4.5 | 1.5 |

Applications

Typical applications for Alleima® 2RK65 are found in oil refineries and within the chemical and petrochemical industry. Alleima® 2RK65 is also used within the pulp and paper industry, the mineral and metallurgical industry, the food industry, in seawater cooling and in many other fields.

The grade is an excellent alternative to standard austenitic stainless steels in heat exchangers using high-temperature water with chloride contamination.

Corrosion resistance

General corrosion

The steel was originally developed for use in sulfuric acid. Its good resistance is achieved by virtue of a high molybdenum content and alloying with copper.

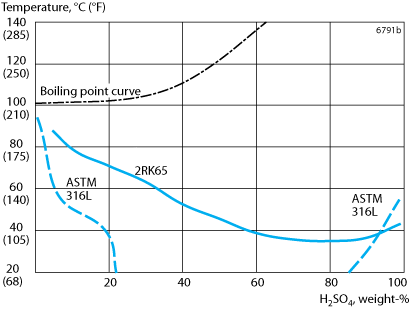

Figure 1 is an isocorrosion diagram for Alleima® 2RK65, Sanicro® 28 and ASTM 316L in deaerated sulfuric acid.

Figure 1. Isocorrosion diagram for Alleima® 2RK65, Sanicro® 28 and ASTM 316L in deaerated sulfuric acid at a corrosion rate of 0.1 mm/year (4 mpy) in stagnant solution.

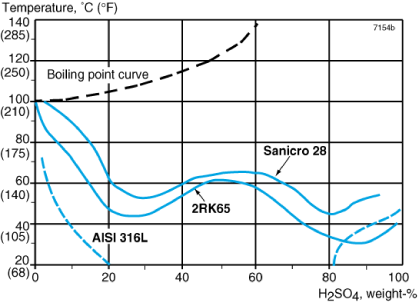

Figure 2 shows the isocorrosion diagram for the above steels but in naturally aerated sulfuric acid.