Overview

AMSE B16.10 overall length

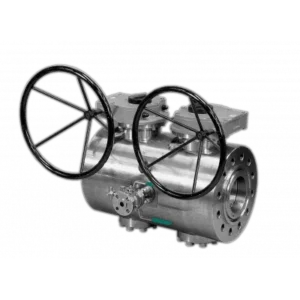

Allows the replacement of single isolate ball valves with the increased safety of true double isolation, without the need for expensive pipework modifications.

The single piece body with threaded end inserts provides the most compact overall length and reduces potential leak points to an absolute minimum.

Valves are available with full bore sizes in accordance with API 6D, ensuring maximum flow for increased production rates and allowing pigging of the pipe line.

Various bleed valve options and connections are available in line with customer requirements.

The floating ball construction ensures maximum weight and space savings, whilst providing reliable and safe isolation up to and including ASME Class 2500

Available up to 3″ full bore and 4″ reduced bore.

Available in ASME B16.10 standard length (CSL).

Also available to Oliver standard lengths (COSL).

Floating Ball design with robust lever operation.

Flanged connections in accordance with ASME B16.5.

Integral vent valve with threaded outlet connection.