Overview

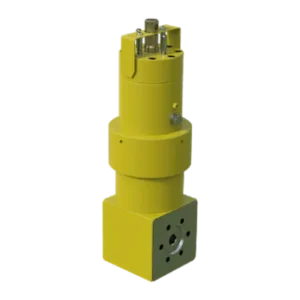

Oliver Valvetek designs and manufactures through conduit style Subsea gate valves.

The gate and seat sealing technology used within the valves utilise fully Qualified Tungsten Carbide hard facing technology to provide a gas-tight sealing meeting with API6A PSL3+G. Our small-bore subsea gate valve range is qualified at different pressure ratings up to 1,034bar (15,000psi).

Qualification testing is performed to the exacting standards of API 6A Appendix F PR2 and 17D 2nd Ed, which is conducted in our own state of the art Research and Development Centre. Compact hydraulic actuators can be supplied for a range of different water depths down to 3,050m (10,000ft).

Product Features

Disc Spring or Coil Spring Fail Close Actuator

The fail close (optional fail open) action is by way of a disc spring stack or coil spring stack. These have been designed and tested for thousands of operating cycles. A 50,000 cycle test was successfully conducted on one set, replicating a complete field service life application. Actuator spring stack can be provided for water depths down to 10,000ft [3050m] with current product developments to consider actuators for ultra-deep water projects in excess of 10,000ft.

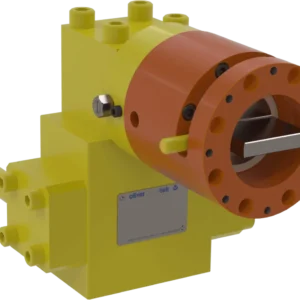

Override Operator

The actuated gate valve can be supplied with an ROV override and where needed an ROV receptacle, which can be used to manually open or close the gate valve in the event of a loss of hydraulic pressure. Different adaptors can be provided for connection to extension rods for ROV operation and can be customised to your specific applications or clients design requirements.

Position Indication

Clear position during both hydraulic and override operation. Oliver Valvetek offer multiple methods of position indication and can customise this application to meet with you requirements.

Hydraulic Actuator Seals

Capped seals or Tee seal hydraulic actuator seals with Peek anti-extrusion rings are used as standard and are suitable for Hydraulic System operational pressures of 5,000psi [345 bar] and have been tested to 7,500psi [517 bar]. Oliver Valvetek can also offer customised seal material solutions if required to meet the demands of specific control fluids and applications. Please contact our Sales our Technical team for further information and support.

Override Operating Threads

The multi-turn ACME thread design ensures low override operating torques.

Uninterrupted flow passage through the valve

The through conduit slab gate and seat design in the fully open position provides clear through bore with minimum restriction to flow. Where connection sizes allow, the gate and seat through bore can be drift tested per the requirements of API6A.

Process connections

The through conduit slab gate can be customised to allow for BX or Stub pipe connections to meet your application requirements. Stub pipe connections can also be provided as a bolt on connector or machined fully integral to the valve’s body.