Overview

Product features

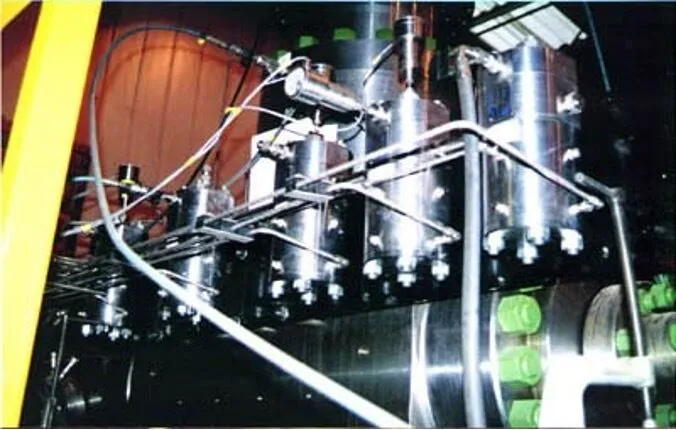

Operator – The needle valves are supplied with a number of different actuators for either shallow or deeper water applications. Optional override with a torque to operate, 120ft-lbf nom, 200ft-lbf max, API17D class 2.

Anti-Blowout Spindle – The needle valve is supplied with a ¾” (19mm) bore that has a spindle designed for maximum torsional (Torque to Damage) strength of 300 ft-lbf.

Environmental Seals – All needle valves have seals to prevent the ingress of seawater. Depending on the application, Hydraulic Needle valves from Oliver Valvetek are designed for water depth equivalent to 4,500 feet (1371m).

Gland Seals – The gland seal within each needle valve has been designed with a spring energised, lower seal to prove dynamic adjustment of the packing gland seal in response to pressure changes. This feature ensures leak-free spindle sealing with no requirement for adjustment.

Traceability of Materials – All the components within an Oliver Valvetek subsea needle valve have material traceability. The needle valve body, tip, spindle, seal housing are manufactured as standard to API 6A PSL3. The complete needle valves are individually serialised and are provided with material and pressure test certificates to BS EN 10204 3.1 certifications. Optional EN 10204 with the intent of a 3.2 type certification option is also readily available (EN 10204 3.2 true mill witnessed shall be assessed for availability upon request).