Features |

|

| Compliance | Standards : CTL – PT / SR/ ZH to EN 62395-1 and CTL – PT to EN 60079-0, EN 60079-30-1 & EN 60079-31. |

| Approvals | CTL-PT:Tested by Central Institute of Mining and Fuel Research (CSIR-CIMFR), Dhanbad And certified by Petroleum & Safety Organization (PESO) / Nagpur, for Zone II , TI (ATEX) for Zone I / Division II & EAC for use in hazardous area applications.

CTL – PT / SR/ ZH : CE and EAC |

| Rugged construction | Outer metallic braid in CTL – PT & CTL – SR makes it robust and suited to hostile conditions. |

| Chemical Resistant | Fluoropolymer insulated Thermotrace CTL is inert to all chemicals, and it is waterproof and weatherproof. |

| Long Life | PTFE has excellent electrical properties, thermal stability, fire resistance and is virtually non – ageing and can withstand the high temperature continuously. |

| Efficient Heat Transfer | Flexible and flat configuration of the Thermotrace CTL enables an intimate contact with the surface to be heated, ensuring efficient heat transfer. |

| Cut to Length | Thermotrace CTL is supplied in continuous long lengths, which can be cut to desired lengths. |

| Custom built | We also offer custom designs of a product to suit individual requirements. We can design for various dimensions and voltages. |

Range

Depending on the application and site conditions (viz. temperature, weather conditions, chemical environment), we can offer options of various insulating materials for Thermotrace CTL to match your individual requirements.

Specifications |

|||||||||||

| Model | CTL ZH | CTL SR | CTL PT | ||||||||

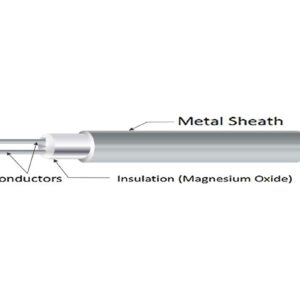

| Bus conductor | 2×1.5sq.mm | 2×1.1sq.mm | 2×1.5sq.mm | ||||||||

| Bus insulation | Polyolefin | Silicon Rubber | Fluoropolymer | ||||||||

| Sheath | Polyolefin | Silicon Rubber | Fluoropolymer | ||||||||

| Braid | Copper /Coated Copper or Stainless Steel | Copper /Coated Copper or Stainless Steel | Coated Copper or Stainless Steel | ||||||||

| Supply Voltage* | 230V | 230V | 230V | ||||||||

| Power Output (W/m) | 10 | 20 | 10 | 20 | 30 | 40 | 16 | 25 | 33 | 45 | 60 |

| Max. circuit length (m) | 160 | 112 | 160 | 100 | 90 | 60 | 125 | 100 | 90 | 75 | 60 |

| Zone length (mm) | 1300 | 1000 | 1300 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 500 |

| Max. Operating Temperature (°C)

(Power On)$ |

40 | 35 | 190 | 175 | 180 | 120 | 220 | 200 | 180 | 165 | 150 |

| Max. Withstand Temperature (Power Off) | 80°C | 180°C | 260°C | ||||||||

| Min. Installation Temperature | -15°C | -50°C | -65°C | ||||||||

| Min. Bend radius | 30mm | 20mm | 25mm | ||||||||

| Packing Length in a Reel | 500m | 500m | 500m | ||||||||

* Can also be custom designed to specified operating voltages.

$ Check the system configuration & design-Contact us for more details.

# Thermopads reserves the right to modify the specifications in line with future improvements, updated standards or updated certifications