Overview

Operator – The ball valves can be supplied with a number of different operators, including Lever and Tee Bars for diver operation or paddles for ROV operation.

Stop Pins – Each ball valve size has a stop pin designed for maximum torsional (Torque to Damage) strength.

Anti-Blowout Spindle – All ball valves have an anti-blowout safety feature.

Environmental Seals – All ball valves have seals to prevent the ingress of seawater. These have been tested to water depths equivalent to 10,000 feet (3050m).

Gland Seals – Each of the Oliver Trunnion Ball valve range have gland sealing technology to suit its specific applications. The gland seal within each ball valve is a Peek thrust ring with a secondary o-ring with a special anti-extrusion ring designed to prove a leak-free spindle sealing with no requirement for adjustment. The 0.5” Trunnion ball valves and above come with an optional secondary polymeric stem seal technology for added safety and reliability.

Ball – All Oliver Valvetek balls are manufactured by its own production facility to ensure stringent Quality control and ball profiling design. The Oliver subsea ball valve range is high precision manufactured to extremely accurate sphericalness, which ensures extended operational life and is highly polished to provide minimum operational torques.

Seats – All ball valves utilise Peek seats which offer broad process compatibility whilst maintaining a positive sealing across the full pressure range from low to maximum working pressure.

Full Flow – Positive 90deg ball travel combined with clear through bore provides minimum restriction to flow.

2, 3 or 4-way Options. – The trunnion mounted ball valves can be provided as either a two, three, or 4-way design.

Traceability of Materials – All the components within an Oliver subsea ball valve have material traceability. The complete ball valves are individually serialised and are provided with material and pressure test certificates to BS EN 10204 3.1 certification and optional EN 10204 with the intent of 3.2 type certification option is also readily available (EN 10204 3.2 true mill witnessed shall be assessed for availability upon request).BS EN 10204 3.1 as standard, 3.2 optional.

Types of Ball Valve:

3/8″ Two-Way / three way / Four way Trunnion Ball Type Subsea Valve

• This valve design utilises a trunnion mounted ball arrangement suitable for operating pressures up to 15,000psi (1034bar).

• 3/8″ Ball Valves can be supplied with any combination of inlet or outlet connection for example MP autoclave, SAE connections. stub pipe connections or threaded NPT. Valves can be supplied for panel mounting with pre drilled/tapped holes and a full compliment or drive adapters or low torque receptacles.

• The 3/8″ two-way valve can be fitted with an alternative ball design and bottom end connector making it so that fluid entering the bottom connection can be diverted to either of the two side end connections. The trunnion design means that whilst flowing from the bottom connection to one of the side connections, the other side connection is fully isolated.

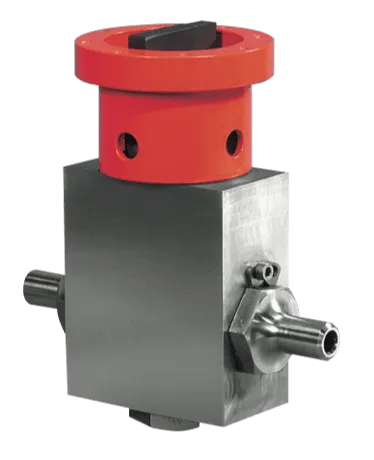

1/2″ Trunnion Ball Valves.

• The 1/2″ bore trunnion ball arrangement is also suitable for operating pressures up to 15,000psi (1034bar). The figure shows a double sealing arrangement of the product. The double sealing valve utilises a spring energised gland seal in series with the normal o-ring spindle seal.

• The 1/2″ ball valve can be supplied with bolt-on end connections rather than the threaded type. The bolt-on connections allow tubes to be welded below the valve rather than inline giving the system designer flexibility to orientate both inlet and outlet positions to their needs and requirements.